A complete plumbing system integrates six essential components that work together to manage water throughout buildings. Water supply pipes and networks deliver clean water, while plumbing fixtures and appliances serve as user interface points. Flow control systems regulate water pressure and distribution, typically maintaining 40-60 psi for peak performance.

Water heating components provide temperature-controlled water for domestic use, and drainage systems remove waste water through strategically designed pipes. Ventilation systems prevent pressure issues and guarantee proper flow throughout the network.

Understanding these core components reveals the complexity behind every functional plumbing installation.

Highlights

- Water supply systems distribute clean water through pipes using various materials like copper, PVC, and PEX with essential control valves.

- Drainage systems remove wastewater through strategically designed pipes, P-traps, and vent stacks to maintain proper flow.

- Water heating systems provide temperature-controlled water through tank or tankless units, requiring regular maintenance for optimal efficiency.

- Ventilation networks prevent vacuum formation and regulate pressure through air stacks and vents throughout the plumbing system.

- Fixture connections and appliance hookups serve as interface points between users and plumbing systems, requiring specific installation requirements.

Water Supply Pipes and Networks

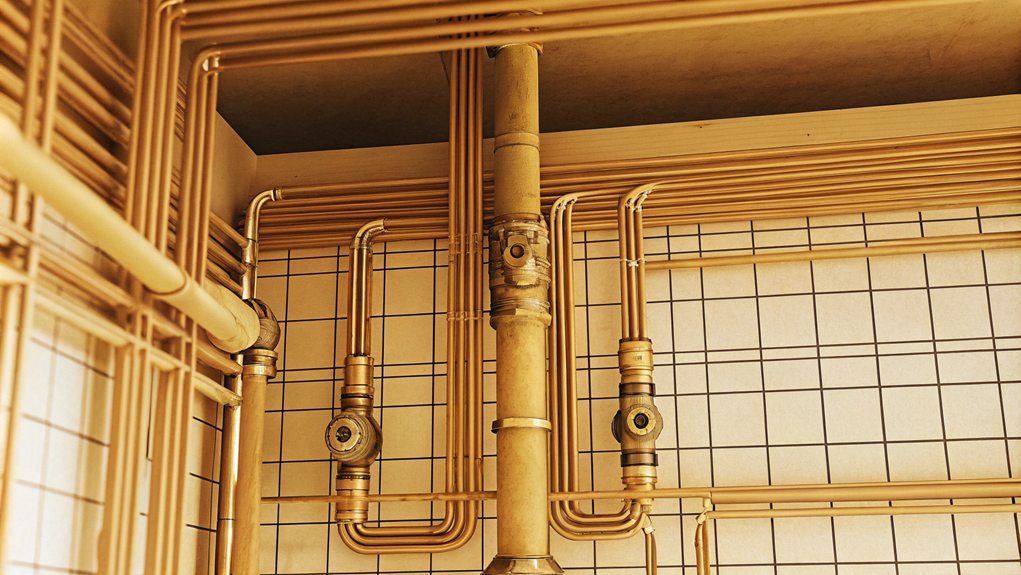

Serving as the lifeline of any building’s plumbing infrastructure, water supply pipes and networks form an essential system that delivers clean, potable water throughout the structure. The network begins at the main plumbing valve, typically situated near the water meter, which serves as the primary control point for the entire water supply system.

Modern water supply pipes are constructed from durable materials, including:

- Copper: Known for longevity and corrosion resistance

- PVC: Offers cost-effective durability

- PEX: Provides flexibility and easy installation

- Stainless Steel: Guarantees maximum strength and durability

Supply lines distribute potable water under pressure to various fixtures throughout the building, including sinks, toilets, and showers.

To facilitate maintenance and localized repairs, individual shut-off valves are installed at each fixture, allowing for isolated service without disrupting the entire plumbing system.

The network can operate through:

- Direct Systems: Water flows straight to fixtures

- Indirect Systems: Utilizes storage tanks for regulated distribution

This thorough network requires proper material selection, strategic valve placement, and regular maintenance to guarantee reliable water delivery throughout the structure.

Plumbing Fixtures and Appliances

Plumbing fixtures and appliances serve as the primary interface points between users and their home’s water supply system, requiring specific installation methods for ideal performance and longevity.

Modern fixtures, such as faucets, toilets, and dishwashers, connect to the main plumbing through standardized fittings and shut-off valves, which allow for easy maintenance and replacement when needed.

Regular inspection and maintenance of these components should occur every 6-12 months, focusing on leak detection, pressure testing, and cleaning of aerators and strainers to guarantee proper functionality and prevent water waste.

Common Fixture Installation Types

Modern residential and commercial buildings rely on a diverse array of plumbing fixtures and appliances, each requiring specific installation methods to guarantee proper functionality and safety.

These installations must conform to established plumbing codes while guaranteeing proper connections to both water supply and drainage systems.

Primary Installation Categories:

- Bathroom Fixtures

- Toilets require precise mounting at 15-17 inches from floor level.

- Sinks need both hot and cold water connections with proper P-trap installation.

- Bathtubs demand careful leveling and secure mounting to prevent leaks.

- Kitchen Components

- Sink installations typically include 8-10-inch basin depths.

- Dishwashers require dedicated water supply lines and drainage connections.

- Garbage disposals need specific electrical and plumbing configurations.

- Major Appliances

- Water heaters demand proper venting systems.

- Installation varies between gas, electric, and tankless models.

- Safety components include pressure relief valves and expansion tanks.

Each fixture type incorporates essential components such as shut-off valves, water supply lines, and drainage connections.

Proper installation guarantees peak performance while preventing common issues like leaks, inadequate water pressure, or improper drainage.

Appliance Water Connection Points

Water connection points represent critical junctures within residential and commercial plumbing systems, serving as the interface between water supply lines and various fixtures and appliances.

These connection points must comply with local building codes to guarantee safety and functionality while maintaining proper drainage throughout the system.

Key Connection Requirements:

- Plumbing fixtures (sinks, toilets, bathtubs)

- Require direct water supply connections

- Need individual shut-off valves for maintenance

- Must meet code requirements for pressure and flow

- Major Appliances (dishwashers, washing machines)

- Demand specific connection types and sizes

- Require both water intake and drainage points

- Need flexible supply lines for vibration control

Proper installation of these connection points is essential for system integrity and maintenance accessibility.

Each fixture and appliance connection must include:

- Appropriate pipe diameter and material

- Properly sealed joints and fittings

- Easy access for repairs and maintenance

- Compatible shut-off valves for isolation

Understanding these connection points allows for efficient troubleshooting and repairs within plumbing systems, preventing potential water damage and guaranteeing peak performance of both fixtures and appliances.

Maintenance Schedule Guidelines

Regular maintenance of fixtures and appliances forms the cornerstone of a reliable plumbing system, ensuring peak performance and preventing costly repairs.

A well-structured maintenance schedule helps homeowners track essential upkeep tasks and extend the life of their plumbing components.

Key Maintenance Intervals:

Monthly to Bi-Monthly:

- Basic fixture maintenance, including sink and toilet cleaning

- Check for visible leaks around supply lines

- Clear surface debris from drains

Semi-Annual Tasks:

- Inspect and clean drain traps to prevent sewer gas infiltration

- Test water pressure at various fixtures

- Replace worn washers and seals in faucets

Annual Requirements:

- Flush water heaters to remove sediment accumulation

- Inspect pipe insulation and exposed plumbing

- Clean aerators and showerheads

Professional Services:

- Schedule thorough plumbing inspection every 1-3 years

- Document all maintenance activities and repairs

- Address any code compliance issues during inspections

Following these maintenance guidelines helps prevent common issues such as clogs, water pressure problems, and premature fixture failure.

Professional inspections complement regular maintenance by identifying potential problems before they become emergencies.

Flow Control and Regulation

Effective flow control and regulation stand at the heart of every well-functioning plumbing system. The intricate network of valves, regulators, and restrictors works together to maintain consistent water pressure and optimal performance throughout a building’s plumbing infrastructure.

Key Components of Flow Control:

- Valves

- Gate valves provide minimal resistance for maximum flow when fully open.

- Ball valves enable quick shut-off capabilities for emergencies.

- Globe valves offer precise flow adjustment for specific applications.

- Pressure Regulators

- Maintain steady water pressure between 40-60 psi.

- Protect plumbing fixtures and appliances from pressure damage.

- Install at main water supply entry points.

- Flow Restrictors

- Integrate into faucets and showerheads.

- Reduce water consumption while maintaining adequate flow.

- Support water conservation initiatives.

Understanding these components’ interactions is vital for system maintenance and troubleshooting.

When properly configured, flow control devices work harmoniously to deliver consistent water pressure, prevent equipment damage, and enhance water usage.

Regular inspection of these components guarantees reliable performance and helps identify potential issues before they escalate into major problems.

Water Heating Components

A building’s hot water supply depends on a sophisticated network of water heating components working in concert. Water heaters, available in gas-powered, electric, and solar variants, form the core of these systems, providing essential hot water for domestic use throughout the structure.

The system’s efficiency relies on several key elements:

- Temperature Control: A thermostat maintains ideal water temperature, typically ranging from 120°F to 160°F, guaranteeing both safety and energy efficiency.

- Storage Solutions: Traditional units utilize storage tanks to maintain hot water reserves, while tankless systems heat water on demand, offering space-saving benefits.

- Insulation Systems: Proper insulation of both the water heater and connecting pipes minimizes heat loss during water delivery, greatly improving overall energy efficiency.

Regular maintenance plays a vital role in system longevity and performance:

- Tank Flushing: Periodic removal of sediment buildup prevents efficiency loss and extends equipment life.

- Component Inspection: Regular checking of heating elements, thermostats, and pressure relief valves.

- Insulation Assessment: Routine evaluation of insulation integrity to maintain ideal thermal retention.

These components require consistent monitoring and upkeep to guarantee reliable hot water delivery and maximum energy efficiency.

Drainage and Waste Management

Managing wastewater effectively requires a thorough drainage system that safely channels waste from plumbing fixtures to municipal sewer lines or septic systems. This complex network relies primarily on gravity to transport waste while maintaining proper ventilation to prevent vacuum pressure and blockages.

| Component | Primary Function | Maintenance Requirement |

|---|---|---|

| Drain Pipes | Transport wastewater | Monthly inspection |

| Vent Stacks | Prevent vacuum formation | Quarterly cleaning |

| P-Traps | Block sewer gases | Bi-monthly cleaning |

| Main Sewer Line | Final waste transport | Annual inspection |

The effectiveness of a drainage system depends on several significant elements working in harmony. Plumbing fixtures connect to individual drain lines that merge into the main sewer line, creating a continuous flow path. Ventilation plays a vital role through vent stacks that allow air movement, preventing pressure-related issues that could impede waste flow.

Proper maintenance guarantees peak system performance. Regular inspection of traps, which retain water to block sewer gases, prevents odor issues and potential blockages. Industry standards recommend cleaning traps every 1-2 months and checking ventilation points quarterly to maintain system efficiency and prevent costly repairs.

Ventilation and Air Systems

Plumbing’s ventilation system serves as the respiratory network that maintains proper air balance and pressure equilibrium throughout the entire drainage infrastructure. Proper venting plays a critical role in guaranteeing that wastewater flows efficiently while preventing harmful sewer gases from entering living spaces.

Key Functions of Ventilation Systems:

- Regulates pressure within pipes to prevent slow drainage and maintain ideal flow

- Allows fresh air circulation to dilute and remove indoor pollutants

- Releases trapped air through strategically placed air vents at system high points

- Prevents backflow issues and protects trap seals

System Maintenance Requirements:

- Regular inspection of all vent stacks and connecting pipes

- Removal of debris, leaves, and other blockages from vent openings

- Verification of proper vent sizing and placement

- Assessment of smooth wastewater flow through drain lines

Professional plumbers recommend quarterly checks of ventilation components to guarantee system integrity.

When properly maintained, plumbing systems operate efficiently and silently. However, warning signs such as gurgling sounds, slow drains, or persistent odors indicate potential ventilation problems requiring immediate attention.

These issues often stem from blocked or damaged vent pipes, which can compromise the entire system‘s functionality.

Frequently Asked Questions

What Are the Various Components Parts of the Plumbing System?

Plumbing systems comprise pipe materials for water supply, drainage systems for waste removal, various fixture types, venting methods for proper airflow, and components requiring regular maintenance practices by plumbing codes and emergency repairs.

What Does a Plumbing System Consist Of?

A plumbing system consists of water supply and drainage systems using various pipe materials, connected plumbing fixtures, and wastewater management components, all installed according to plumbing codes with proper maintenance and leak detection protocols.

What Are the Parts of the Plumbing Plan?

A thorough plumbing plan includes water supply layouts, drainage design, plumbing fixtures placement, venting systems, pipe materials specifications, installation techniques, maintenance practices, leak detection protocols, and compliance with plumbing codes.

What Is Plumbing Fundamentals?

Plumbing fundamentals encompass pipe materials, drainage design, water pressure management, and adherence to plumbing codes. It includes understanding fixture types, maintenance practices, proper installation techniques, leak detection, and plumbing safety protocols.

Final Thoughts

A properly functioning plumbing system relies on the seamless integration of six essential components: water supply, fixtures, flow control, heating, drainage, and ventilation. Each element serves a critical role in maintaining safe, efficient water distribution and waste removal throughout residential and commercial structures.

Understanding these core components enables effective maintenance, troubleshooting, and system optimization, ultimately ensuring reliable water service and sanitation for building occupants.